In the realm of manufacturing, time has always been a critical factor. Traditional manufacturing processes, with their inherent limitations, often consume valuable time and leave room for errors that can be costly both in terms of resources and reputation. The need for a transformative solution that addresses these challenges has never been more pressing.

For decades, factories have relied on conventional manufacturing processes which come with their fair share of challenges. These processes are often time-consuming, leading to delays in production timelines.

The Need for a Revolutionary Solution

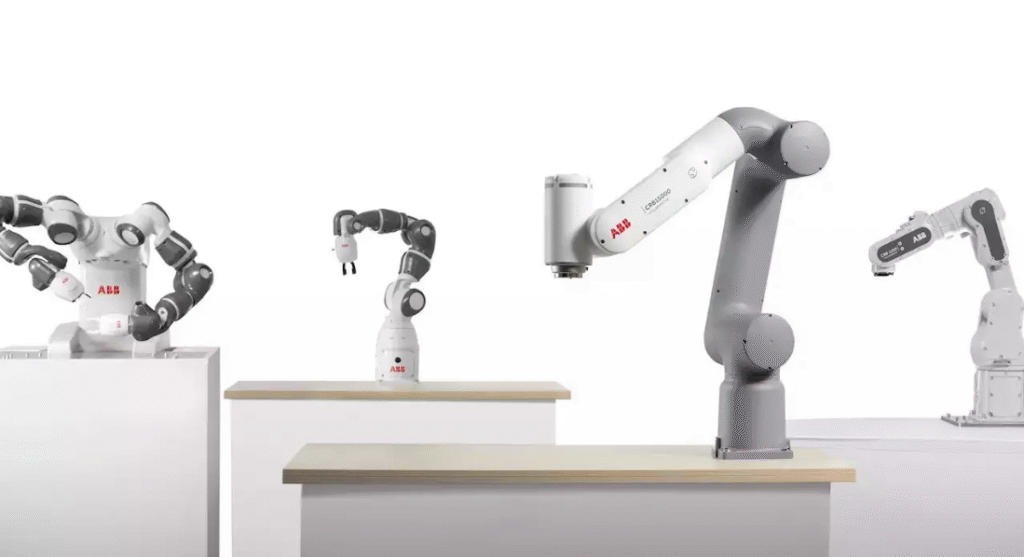

The manufacturing industry’s hunger for innovation has paved the way for a remarkable era: the age of robotic innovation. Advanced robotics, driven by artificial intelligence (AI) and automation technologies, are reshaping the manufacturing landscape. These robotic systems offer a promising solution to the limitations of traditional manufacturing processes, heralding a new era of efficiency, precision, and excellence.

- Innovations in AI robots

AI-driven robotics have taken centre stage in manufacturing. These robots are not just machines; they are intelligent collaborators that can seamlessly integrate with human workers to enhance operational capabilities.

- Collaborative robots

One of the most groundbreaking aspects of robotic innovation is collaborative robots, often referred to as “cobots.” These robots are designed to work alongside human operators, assisting them in tasks that require precision, strength, and speed.

- Precision and accuracy

The margin for error in manufacturing is minimal. AI robots excel in precision and accuracy, reducing errors in critical processes such as assembly and quality control. This heightened accuracy translates to higher product quality and fewer defects.

- Overcoming shortages with robots

The manufacturing industry has been grappling with a shortage of skilled labour. AI robots bridge this gap by taking over repetitive and labour-intensive tasks, allowing human workers to focus on more strategic and creative aspects of production.

- Applications of robotic innovation in manufacturing

Robotic automation optimizes production lines by minimizing downtime, ensuring consistent output, and speeding up processes. This leads to increased efficiency and a higher volume of products produced.

- Quality control and consistency

AI robots employ advanced sensors and machine vision to perform meticulous quality checks. This reduces product defects, maintains consistent quality, and upholds the reputation of the brand.

- Ensuring worker safety

Robotic systems are equipped to handle hazardous tasks that pose risks to human workers, such as working with toxic chemicals or in environments with extreme temperatures.

- Real-time data analytics

AI robots collect and analyze real-time data, providing valuable insights into production processes. This data-driven approach empowers manufacturers to make informed decisions and optimize operations further.

- Scaling operations

As demand for products increases, traditional manufacturing processes often struggle to keep up. Robotic innovation allows for easy scalability, ensuring that production can be ramped up to meet market demands.

The age of robotic innovation is upon us, and its impact on the manufacturing landscape is undeniable. Advanced autonomous robots are not just machines; they are collaborators, enablers, and catalysts of excellence. By harnessing the power of robotic innovation, manufacturers can unlock new levels of efficiency, precision, and productivity. Novus Hi-Tech’s Autonomous Mobile Robots are transforming the manufacturing process by reducing production cost and time and increasing efficiency. Novus Hi-Tech is leading the future of manufacturing and those who embrace it are poised to lead the charge into a new era of excellence.