In the dynamic landscape of supply chain management, warehouses are undergoing a transformative shift, marked by the integration of advanced technologies. Warehouse automation has emerged as a pivotal force, reshaping traditional logistics practices and fostering efficiency in the modern era.

Understanding What is Warehouse Automation?

Warehouse automation represents a paradigm shift in the way goods are stored, retrieved, and managed within distribution centers. At its core, it involves the use of technology to perform tasks traditionally carried out by human operators. This ranges from simple conveyor systems to sophisticated robotic solutions, all aimed at optimizing operational workflows.

Top Warehouse Automation Trends and Technologies in the Modern Era

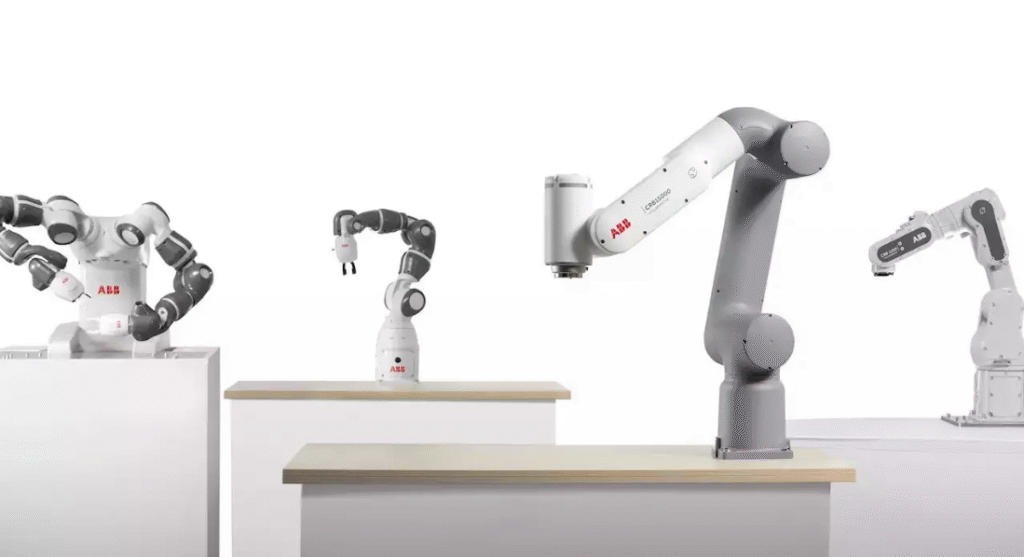

- Automated Guided Vehicles (AGV) and Autonomous Mobile Robots (AMR)

AGVs and AMRs are redefining material handling within warehouses. These autonomous entities navigate the facility, transporting goods with precision and efficiency. Their adaptability to varying tasks enhances overall operational flexibility.

- Automated Storage and Retrieval Systems (ASRS)

ASRS utilizes robotic systems to manage inventory, enabling high-density storage and retrieval with minimal human intervention. This technology enhances speed and accuracy, crucial factors in today’s fast-paced supply chain.

- Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML algorithms empower warehouses to analyze vast datasets, optimize processes, predict demand, and streamline decision-making. These technologies enhance overall operational intelligence and responsiveness.

- Blockchain Technology

Blockchain’s decentralized ledger ensures transparent and secure transactions, benefiting the supply chain by providing a tamper-resistant record of every transaction. This not only enhances traceability but also minimizes the risk of errors and fraud.

- Internet of Things (IoT)

IoT connects devices and equipment, facilitating real-time data exchange. In warehouses, IoT enables proactive maintenance, inventory tracking, and condition monitoring, contributing to improved operational visibility.

- Inventory Management System

Advanced inventory management systems leverage technology to optimize stock levels, reduce excess inventory, and minimize stockouts. These systems enhance accuracy and responsiveness in meeting customer demands.

- Fleet Management System

Efficient fleet management systems ensure the optimal use of vehicles within warehouses. From route optimization to predictive maintenance, these systems contribute to cost savings and operational efficiency.

Benefits of Warehouse Automation

- Reduced Labor Costs

Automation diminishes the reliance on manual labor, leading to reduced labor costs. Repetitive tasks are delegated to machines, allowing human resources to focus on higher-value activities.

- Improved Accuracy and Productivity

Automation minimizes errors associated with human intervention, leading to increased accuracy in tasks such as order picking and packaging. Simultaneously, productivity surges with the precision of automated systems.

- Greater Safety and Security

With automation, the risk of workplace accidents diminishes. Robots and machines are designed with safety features, contributing to a secure working environment. Additionally, automated systems enhance data security through controlled access.

How Novus Hi-tech is Taking a Revolutionary Leap

Novus Hi-tech stands at the forefront of warehouse automation, integrating state-of-the-art technologies to revolutionize supply chain management. By leveraging AI, robotics, and IoT, Novus Hi-tech ensures a seamless, agile, and responsive warehouse ecosystem. Their commitment to innovation aligns with the ever-evolving needs of modern businesses, providing them with a competitive edge in the dynamic market.

Wrapping Up

Warehouse automation is not merely a trend; it’s a necessity in the modern era of supply chain management. The convergence of technologies like AI, robotics, and IoT is reshaping warehouses into agile hubs of efficiency, ensuring businesses stay ahead in the race for optimal operational performance. As we navigate the trends of warehouse automation, the future with Novus Hi-tech promises a landscape where innovation and efficiency converge to redefine the very essence of logistics.