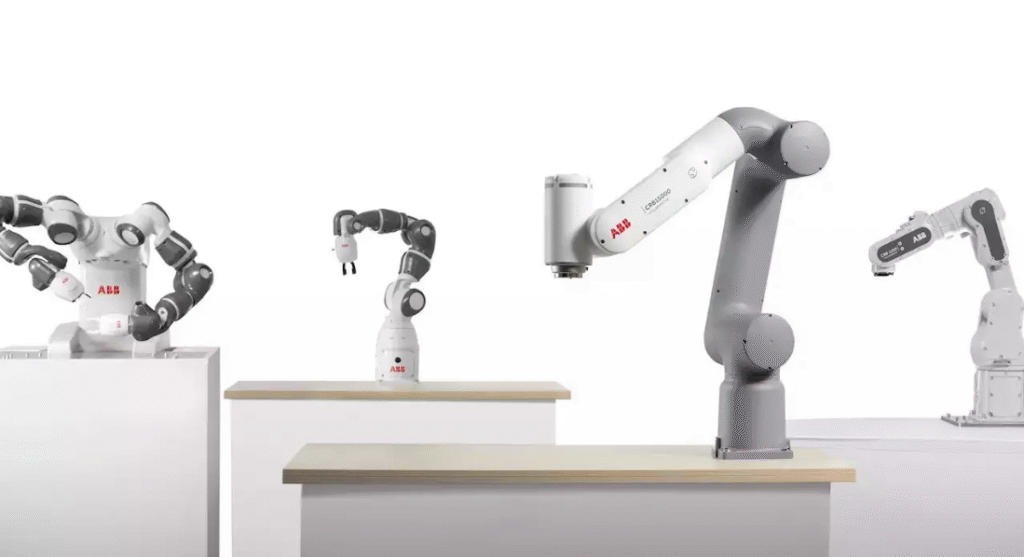

Robots have demonstrated their plus points in the automotive industry and the Indian market has embraced it with open arms. A number of activities from the production process such as welding and painting are being handed over to the robots with an aim to manufacture enhanced vehicles.

India´s robot sales surged by 30 % in 2017, states a 2019 report by the International Federation of Robotics (IFR). The report further expands that the automobile industry is the main demand driver for industrial robots in the Asian country. Most of the major car manufacturers in India have adopted robots in their processes to improve productivity and enhance the quality of their respective vehicles. Robots are usually responsible for performing monotonous work with efficiency on the shop floor. This enables human workers to upgrade their skills so that they can execute other high end tasks which require specific specialisations.

India’s robotic footprint

One of the country’s leading carmaker Tata Motors utilises seven spot welding robots in its framing stations at the Pune and Sanand plants. The automated welding process ensures safety as well as stability in the production of vehicles. Maruti Suzuki India makes use of 5,000 robots at its Manesar and Gurgaon plants in Haryana. The robots are being used in the automated weld, paint and press shops. In addition to this, automobile giant Mahindra & Mahindra carries out about 70 % of its body shop work via robots.

Multinational automobile companies that have set up their manufacturing bases in India have also contributed to the rise in demand of industrial robots in the country. For instance, the American automaker Ford Motor Company makes use of around 450 robots to paint vehicles and carry out processes for body construction at its Sanand plant in Gujarat. More recently, the South Korean multinational car producer, Hyundai Motor Company rolled out its maiden ‘Hyundai Venue’ automobile which was exclusively ‘Made in India’ at its new manufacturing plant in Chennai. The state-of-the-art facility is equipped with over 590 – Generation 4 robots, quality and testing capabilities along with flexible engine plants that are completely equipped for the production of the ‘Venue’ automobile.

This is just the beginning, with India exploring the dimensions of Industry 4.0, one can expect a significant increase in the demand for industrial robots in the years to come.