As the world edges closer to 2025, the advancements of Industrial Revolution 4.0 (Industry 4.0) continue to reshape industries globally. However, just as industries are mastering this phase of digital transformation, Industry 5.0 is beginning to emerge on the horizon. Industry 5.0 builds on the foundations of 4.0 but pivots towards a more human-centric approach, blending automation with human creativity and personalized solutions. This evolution signifies not just technological advancement but a harmonious collaboration between humans and machines, emphasizing sustainability, resilience, and societal well-being

What Is Industrial Revolution 4.0?

Industrial Revolution 4.0 can be described as a very basic term: advanced technology incorporation into industry and manufacturing activities. The heart and soul of these smarter and more productive systems in the new time is presented through IoT, AI, robotics, and big data analytics. This change is unique compared to others due to the principle that it is for automation and real-time data-centric decisions for the first time since the Industrial Revolution 4.0.

Key technologies driving Industrial Revolution 4.0 include:

- IoT: Communicates machines and devices as if they were talking.

- AI and Machine Learning: This enables smarter automation with predictive potential.

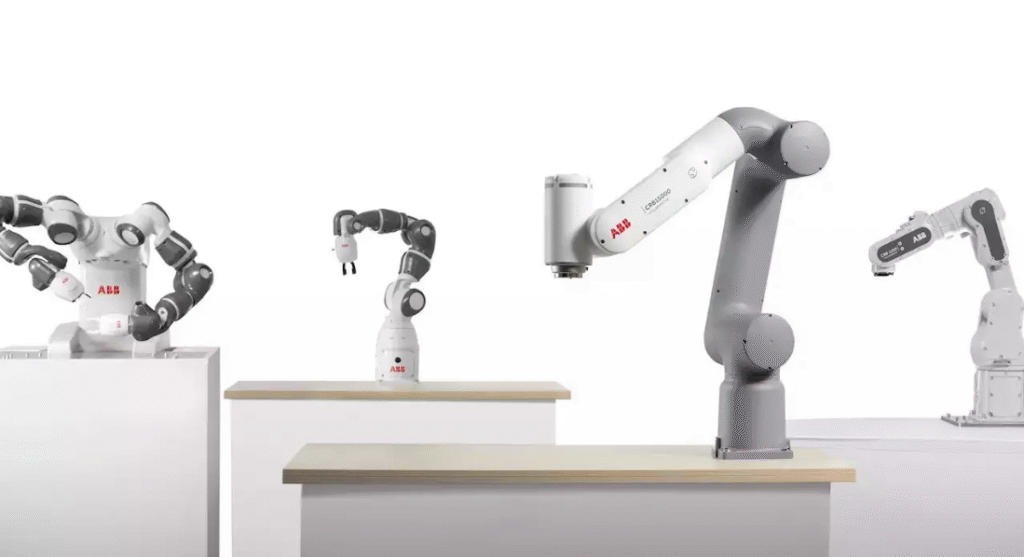

- Robotics: In manufacturing, it enhances precision and productivity.

- Big Data: It provides insights through real-time data collection and analysis.

Key Components of the Industrial 4.0 Revolution

- Smart Factories: Smart factories are the act of bringing technologies such as the IoT and artificial intelligence to achieve Industry 4.0 reformation. Unlike digital systems, activities are categorized into a single automated activity which in turn leads to fewer interruptions as all production processes are followed.

- Cyber-Physical Systems (CPS): A cyber-physical system interconnects digital networks with a physical process. Thus, a system can be designed where both humans and machines can create results that are more productive and effective.

- Big Data Analytics: In a way, big data helps make crucial decisions, with real-time collection and analysis of data. It predicts trends improves quality and increases the satisfaction level of customers toward companies.

Benefits of Industrial Revolution 4.0

Industrial Revolution 4.0 brings transformative benefits that redefine operational efficiency:

- Enhanced Efficiency and Productivity: Minimum human interference due to automation results in faster and more accurate production.

- Better Decision-Making: The organizations make decisions having real-time data to respond effectively to the changing trends in the market.

- Sustainability: Industrial Revolution 4.0 leads to green operations due to efficientresourcese and energy consumption.

- Cost Savings: Utilizing predictive maintenance and effective workflow management could help greatly in lowering the costs of operations.

Challenges of Industrial Revolution 4.0

Industry 4.0 also poses fa ew dilemmas to organizations:

- High Implementation Costs: These cutting-edge technologies involve substantial up-front costs.

- Skilled Workforce Requirement: IoT, AI, as well as robotics experts, are not readily available.

- Data Security Concerns: The system is more dangerous for cyberattacks while more connected.

- Resistance to Change: Traditional industries shun the new technology.

Why Industrial Revolution 4.0 Matters in 2025

As we approach 2025, the importance of Industry 4.0 grows exponentially. Companies are adopting automated technologies to enhance efficiency, reduce costs, and drive innovation. However, this transformation is just the beginning. Industry 5.0 is already gaining traction, emphasizing the need to balance automation with human ingenuity.

- Improved Efficiency: The integration of such automated technologies will abolish inefficiencies by automating processes within different industries.

- Sustainability: The process would be more environmentally friendly

- Cost Savings: Predictive maintenance, in combination with big data analytics, will reduce waste and serve to maximize material resources.

- Innovation: Continuous innovations emerging from artificial intelligence and IoT push every sector to innovate to be competitive.

The Future of Industrial Revolution 4.0 and the Rise of Industry 5.0

The journey of Industry 4.0 doesn’t conclude in 2025. Emerging trends suggest that Industry 5.0 will focus on creating personalized, human-centered solutions. While Industry 4.0 is about machines and data, Industry 5.0 emphasizes collaboration between machines and humans, enhancing productivity without sacrificing creativity.

Key trends of Industry 5.0 include:

- Growth of Autonomous Systems: Cars, drones, and robotics will redefine logistics and manufacturing.

- Expansion Beyond Manufacturing: Sectors like healthcare, agriculture, and education are integrating Industry 4.0 technologies.

- Human-Machine Collaboration: Industry 5.0 aims to combine human creativity with automated efficiency, fostering innovation and sustainable practices.

Conclusion

Industrial Revolution 4.0 is transforming the way industries operate, laying the foundation for a smarter, more automated future. As businesses look ahead to 2025 and beyond, the emergence of Industry 5.0 promises a new era of industrial collaboration where technology not only enhances productivity but also aligns with human values. By embracing this dual transformation, industries can unlock unprecedented growth and innovation while fostering a more sustainable and inclusive future.

FAQs

What is Industrial Revolution 4.0?

The combination of IoT, robots, and big data analytics will be the basis of the Industrial Revolution 4.0, thereby improving operational efficiency across all sectors of the industry.

What are the key benefits of Industrial Revolution 4.0?

The major benefits are considerable improvements in efficiency, better quality of decisions made by firms, and higher energy consumption for industrialized purposes.

What challenges do businesses face with Industrial Revolution 4.0?

The increase in implementation costs and their need for specialized skills, data security issues, and even reluctance to technology advancement are the challenges that business owners will have to face.

How can businesses prepare for Industrial Revolution 4.0?

The implementation costs of specialized skills, data security issues, and reluctance toward technology advancement will be some of the issues to be dealt with by business owners.

How is Industrial Revolution 4.0 different from previous industrial revolutions?

The Industrial Revolution 4.0 means an increase in the mechanization, instantaneous handling of data and also networking that will give space for the emergence of intelligent and adaptive industries.