Warehouse distribution is a cornerstone of the global supply chain, ensuring that products move efficiently from manufacturers to consumers. As technology advances, the landscape of warehouse distribution is undergoing a significant transformation. From automation and robotics to artificial intelligence and the Internet of Things (IoT), the future of warehouse distribution promises increased efficiency, reduced costs, and enhanced capabilities. In this blog, we will explore the key trends and innovations shaping the future of warehouse distribution.

1. Automation and Robotics

One of the most significant trends in warehouse distribution is the adoption of automation and robotics. Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) are becoming increasingly common in warehouses. These robots are designed to move goods efficiently, reduce human labor, and minimize errors.

- AGVs and AMRs: These robots navigate through warehouses using sensors and maps, transporting goods between different areas. They can work around the clock, increasing productivity and reducing the need for manual labor.

- Robotic Picking Systems: Robotic arms equipped with advanced vision systems can pick and place items with precision. This technology reduces errors and speeds up the picking process, leading to faster order fulfillment.

- Automated Storage and Retrieval Systems (AS/RS): AS/RS are used to store and retrieve products from storage locations automatically. These systems optimize space utilization and improve inventory accuracy.

2. Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning are revolutionizing warehouse distribution by enabling smarter decision-making and predictive analytics.

- Demand Forecasting: AI algorithms analyze historical data and market trends to predict future demand accurately. This helps warehouses manage inventory levels more effectively, reducing the risk of overstocking or stockouts.

- Route Optimization: AI-powered software can optimize delivery routes in real-time, considering factors such as traffic conditions, weather, and delivery priorities. This results in faster delivery times and reduced transportation costs.

- Predictive Maintenance: Machine learning models can predict when equipment is likely to fail, allowing for proactive maintenance. This minimizes downtime and ensures smooth operations.

3. Internet of Things (IoT)

The IoT is transforming warehouse distribution by providing real-time visibility and control over operations. IoT devices collect and transmit data, enabling better monitoring and management of warehouse activities.

- Real-Time Tracking: IoT sensors attached to products and pallets provide real-time location tracking. This enhances inventory accuracy and helps prevent loss or theft.

- Environmental Monitoring: IoT devices monitor environmental conditions such as temperature and humidity, ensuring that perishable goods are stored in optimal conditions.

- Equipment Monitoring: IoT sensors track the performance of warehouse equipment, identifying issues before they lead to failures. This improves equipment reliability and reduces maintenance costs.

4. Warehouse Management Systems (WMS)

Warehouse Management Systems (WMS) are software solutions designed to optimize warehouse operations. Modern WMS platforms are becoming more sophisticated, integrating with other technologies to provide a comprehensive solution.

- Inventory Management: WMS systems track inventory levels in real-time, providing accurate data on stock availability. This helps prevent overstocking and stockouts.

- Order Fulfillment: WMS platforms streamline the order fulfillment process, from picking and packing to shipping. They ensure that orders are processed quickly and accurately.

- Labor Management: WMS systems optimize labor allocation, ensuring that workers are assigned tasks efficiently. This improves productivity and reduces labor costs.

5. Sustainable Practices

Sustainability is becoming a critical focus in warehouse distribution. Companies are adopting eco-friendly practices to reduce their environmental impact and meet regulatory requirements.

- Energy Efficiency: Warehouses are incorporating energy-efficient lighting, heating, and cooling systems. Solar panels and other renewable energy sources are also being used to power warehouse operations.

- Waste Reduction: Companies are implementing waste reduction strategies, such as recycling and using biodegradable packaging materials. This reduces the environmental footprint of warehouse activities.

- Green Building Design: Sustainable building designs, such as LEED-certified warehouses, are becoming more common. These buildings are designed to minimize energy consumption and reduce greenhouse gas emissions.

6. Augmented Reality (AR) and Virtual Reality (VR)

AR and VR technologies are enhancing warehouse operations by improving training and increasing efficiency.

- Training: VR-based training programs simulate real-world scenarios, allowing workers to learn and practice in a safe environment. This reduces the risk of accidents and improves worker performance.

- Picking and Packing: AR glasses provide workers with real-time information, such as item locations and packing instructions. This speeds up the picking and packing process and reduces errors.

7. Blockchain Technology

Blockchain technology is being explored for its potential to improve transparency and security in the supply chain.

- Traceability: Blockchain provides a secure and immutable record of product movements, ensuring transparency and traceability. This is particularly important for industries such as food and pharmaceuticals, where product safety is critical.

- Smart Contracts: Smart contracts automate and enforce agreements between parties, reducing the need for intermediaries. This streamlines transactions and reduces the risk of fraud.

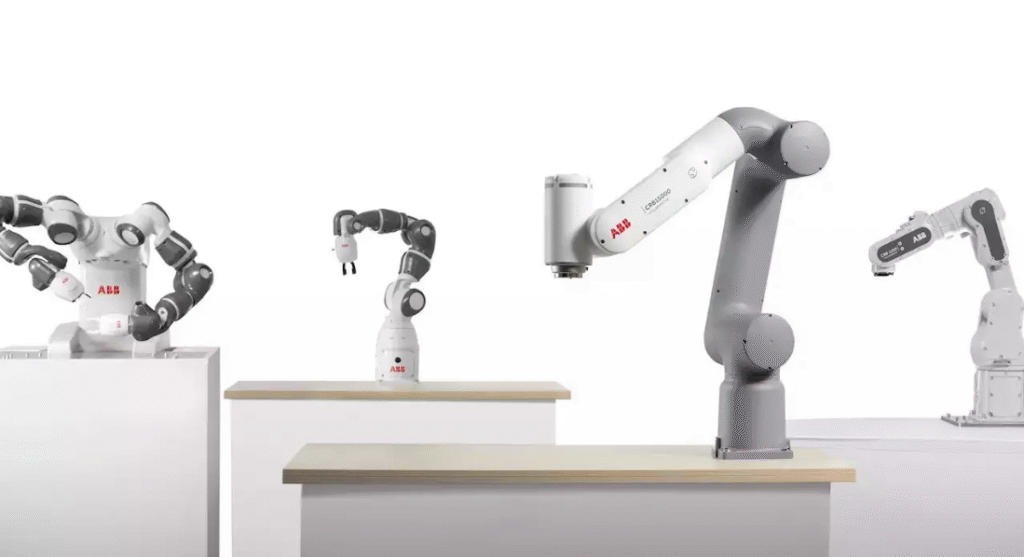

8. Collaborative Robots (Cobots)

Cobots are designed to work alongside human workers, enhancing productivity and safety.

- Safety: Cobots are equipped with advanced sensors and safety features, allowing them to operate safely in close proximity to humans. They can assist with tasks such as lifting heavy objects and performing repetitive actions.

- Flexibility: Cobots are easy to program and can be quickly reconfigured for different tasks. This makes them ideal for warehouses with dynamic workflows and varying demands.

Conclusion

The future of warehouse distribution is being shaped by a combination of advanced technologies and innovative practices. Automation and robotics, AI and machine learning, IoT, WMS, sustainability, AR and VR, blockchain, and cobots are all playing a pivotal role in transforming warehouse operations.

As these technologies continue to evolve, warehouses will become more efficient, cost-effective, and adaptable. Companies that embrace these innovations will be better positioned to meet the demands of an increasingly complex and fast-paced global supply chain. The future of warehouse distribution is not just about keeping pace with technological advancements but leveraging them to create a smarter, safer, and more sustainable supply chain.

Novus Hi-Tech is at the forefront of these innovations, offering cutting-edge solutions to help businesses navigate the evolving landscape of warehouse distribution. By partnering with Novus Hi-Tech, companies can harness the power of advanced technologies to optimize their operations and stay ahead in the competitive market. Visit Novus Hi-tech to learn more about how we can help transform your warehouse distribution processes for the future.