In today’s rapidly evolving industrial landscape, automation has emerged as the cornerstone of progress. Novus Hi-Tech, a leading innovator in manufacturing solutions, stands at the forefront of this revolution. As we delve into the symbiotic relationship between robotics and manufacturing, it becomes evident that the future lies in embracing automation to elevate productivity, efficiency, and quality standards.

Revolutionizing Manufacturing Through Robotics

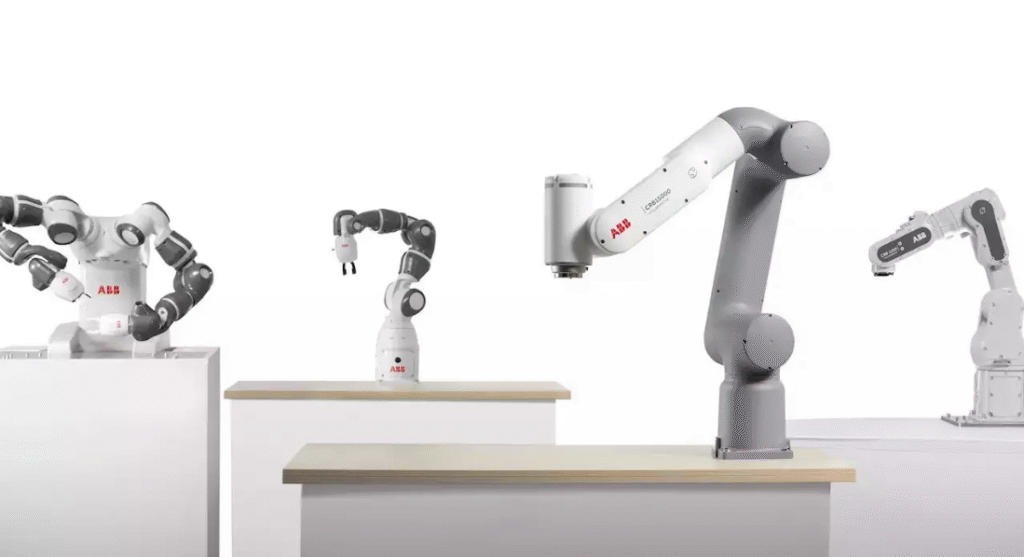

Gone are the days when manufacturing relied solely on manual labor and cumbersome processes. Tasks that once demanded hours of human effort can now be completed in minutes, thanks to advanced robotic systems. With the advent of robotics, the industry has witnessed a paradigm shift in efficiency, precision, and productivity. Robotics have streamlined operations, minimized errors, and accelerated production timelines, marking a stark departure from traditional methods.

Applications of Robotics in Manufacturing

- Assembly Line Automation: Robotics streamline assembly processes, enhancing productivity and reducing errors by executing repetitive tasks with precision.

- Material Handling: Robots excel in the efficient movement and transfer of materials within manufacturing facilities, minimizing the risk of accidents and injuries to human workers.

- Quality Control: Advanced sensors and AI algorithms enable robots to perform intricate quality checks, ensuring products meet stringent standards without compromising on speed or accuracy.

- Inventory Management: Automated inventory systems integrated with robotics optimize stock levels, minimize wastage, and facilitate just-in-time manufacturing practices.

- Flexible Manufacturing: Collaborative robots, or cobots, work alongside human operators, offering flexibility in production setups and enabling quick reconfiguration for diverse product lines.

Benefits of Robotics in Manufacturing

- Increased Efficiency: Robots operate 24/7 without fatigue, significantly boosting production output and reducing lead times.

- Enhanced Safety: By assuming high-risk tasks, robots mitigate workplace accidents and minimize occupational hazards, prioritizing employee welfare.

- Cost Savings: Though initial investments may be substantial, the long-term cost-effectiveness of robotics, through reduced labor costs and enhanced operational efficiency, is undeniable.

- Agility and Scalability: Flexible robotic systems adapt to fluctuating production demands seamlessly, offering scalability without compromising performance.

- Innovation Catalyst: Robotics pave the way for innovation by fostering the development of advanced technologies, propelling manufacturing into the future.

- Quality Assurance: Advanced sensors and algorithms enable robots to maintain consistent quality standards, minimizing defects and waste.

The Future of Robotics in Manufacturing

Looking ahead, the trajectory of robotics in manufacturing is poised for exponential growth. Advancements in artificial intelligence, machine learning, and collaborative robotics will further blur the lines between human and machine interaction. From autonomous mobile robots navigating factory floors to swarm robotics orchestrating intricate assembly tasks, the possibilities are limitless.

In conclusion, the convergence of manufacturing and robotics represents a paradigm shift with far-reaching implications. As industries worldwide embrace automation to stay competitive in an increasingly dynamic marketplace, the role of pioneers like Novus Hi-Tech becomes indispensable. For companies seeking to harness the transformative power of robotics in their operations, partnering with Novus Hi-Tech is the first step towards unlocking a future of unparalleled efficiency and innovation.

Contact us today to explore customized solutions tailored to your unique needs and propel your business toward success.