In this fast-moving world of logistics and supply chain management, warehouse efficiency has become more vital than ever. Advanced robotics brought new innovative technologies for robots, such as fork-based mobile robots, which are gaining extensive traction presently in radically changing the conventional running of warehouses to bring in a new degree of mechanization that directly contributes to improvement in the efficiency of warehouses. In this post, we are going to talk about what fork-based mobile robots are, their role in warehouse operations, and how they improve warehouse efficiency.

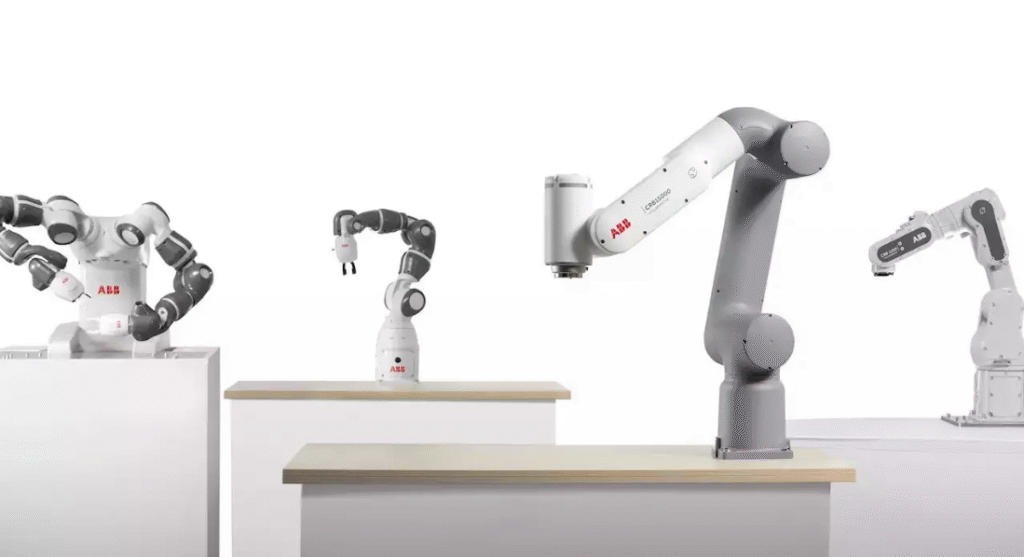

What are Fork-Based Mobile Robots?

Fork-base mobile robots are next-generation forklifts on steroids. They do autonomous processing, transporting, and arranging of goods around a warehouse—much the same as a traditional forklift would. Instead of being human-driven, the robots—get this—motor around a warehouse with ease, moving pallets from one place to another without a hitch.

What sets these robots apart from being mere automated forklifts is that they are very smart. They are endowed with very advanced sensors, artificial intelligence-based navigation, and real-time data processing capabilities. They do not just shuffle things; they can get commands for the optimization of routes while seamlessly interacting with other systems in the WMS.

That’s the level of integration to make a difference in warehouse operations. It reduces human error, reduces operational downtime, and maximizes the utilization of every inch of the warehouse. In short, fork-based mobile robots have taken the lead toward a more efficient and streamlined warehouse.

How Fork-Based Mobile Robots Improve Warehouse Efficiency

Increased Speed and Accuracy: Fork-based mobile robots are designed to run at speeds and precision much higher than humanly possible. They can work continuously without any breaks, so there is no break in operations. It largely accelerates productivity—a rather critical attribute to warehouse efficiency. Also, the accuracy with which the robots handle and place goods massively reduces errors that frequently lead to delays at great costs.

Maximizing Space: Space optimization is one of the challenges of managing a warehouse. The contribution of this from mobile robots with a fork is in making tight placements in the warehouse whereby human operators might find hardship in making their way through. These robots work to reduce clutter by better-sorting goods, hence facilitating easy reach of items whenever needed, hence an efficient warehouse.

Labour Cost: It is one of the biggest costs to a company; therefore, reducing such costs via the use of fork-based mobile robots lessens the need for manual labor. This would not only reduce labor costs but also minimize the risk of workplace injuries that turn out to be a big source of downtime and inefficiency. Humanly handling the bulk of the workload, these robots shall free humans from doing other complex assignments that would further improve the organization’s efficiency.

Real-Time Data and Decision Making: Given their sensor-enabled features, forked mobile robots are connected to the warehouse management system to collect real-time information for analysis. This enables any manager within a warehouse to correct decisions on the spot, by making any changes in routes, realigning resources, or planned maintenance. Such responsiveness in real-time is critical in enhancing the efficiency of warehouses, particularly in environments in which demand may surge quickly.

Scalability & Growth: Businesses translate to increased complexity in warehouse operations. Fork-based mobile robots offer a scalable solution to this problem. Other robots can very well be deployed with minimal disturbance to current operations and easily integrated with the current WMS. Such scalability is important for businesses aiming to better warehouse efficiency—growth in demand without a growth in cost—within businesses.

Sustainability: Sustainability is becoming an increasingly important aspect of warehouse operations. Fork-based mobile robots are energy efficient and reduce wastage. Additionally, the fact that they deliver accurately means that the reduction in damage to goods and equipment as such lessens the resources that would have been spent on repair and replacement. Besides, they could run on renewable energy, meaning all the more environmentally friendly in the operation of a warehouse.

Conclusion

Fork-based mobile robots are a critical game-changer in the efficiency of a warehouse towards its automation, optimization of space, labor cost saving, and enabling real-time decision-making. With the technology evolving day by day, one can only expect more complexity and further additional capabilities that are to be added which furthers their role in a warehouse.

No longer an option now but a must for businesses that wish to keep themselves in the fast lane of the market, an investment in fork-based mobile robots is turning over the wheels of warehouse efficiency today and setting the benchmarks for warehouses of the future.

Want to supercharge the efficiency of your warehouse? Contact Novus HiTech today to know how our innovative solutions can change operations like yours into models of highly effective business management. Let us build the future of efficient warehousing together!